What is the purpose of an Eyewash Station Log Sheet?

The Eyewash Station Log Sheet is used to document the weekly inspection of emergency eyewash fixtures. Its main purpose is to ensure that the eyewash station is functional and ready for use in case of an emergency. Regular inspections help to verify that the station is unobstructed and that the water flow is clear, which is essential for effectively flushing harmful substances from the eyes.

What should I check during the weekly inspection?

During the weekly inspection, you should verify several important aspects of the eyewash station. First, ensure that the pathway leading to the station is clear of any obstructions. Next, check that the eyewash fixture itself is free from blockages in all directions. Removing any accumulated dust or debris from the nozzle dust caps or covers is also necessary, as this ensures they are operating properly. Finally, conduct a water flow test by turning on the eyewash and allowing it to run until clear water flows continuously without any leaks or impurities for about five seconds.

What should I do if I find a problem during the inspection?

If you discover any issues during your inspection, it is important to address them promptly. For problems related to the eyewash station, such as leaks, rust, or insufficient water flow, you should immediately contact the Physical Plant at extension 8-5661 for assistance. If you have general questions about eyewash stations, don’t hesitate to reach out to Safety Affairs at extension 8-6114. They can provide guidance and help resolve any concerns.

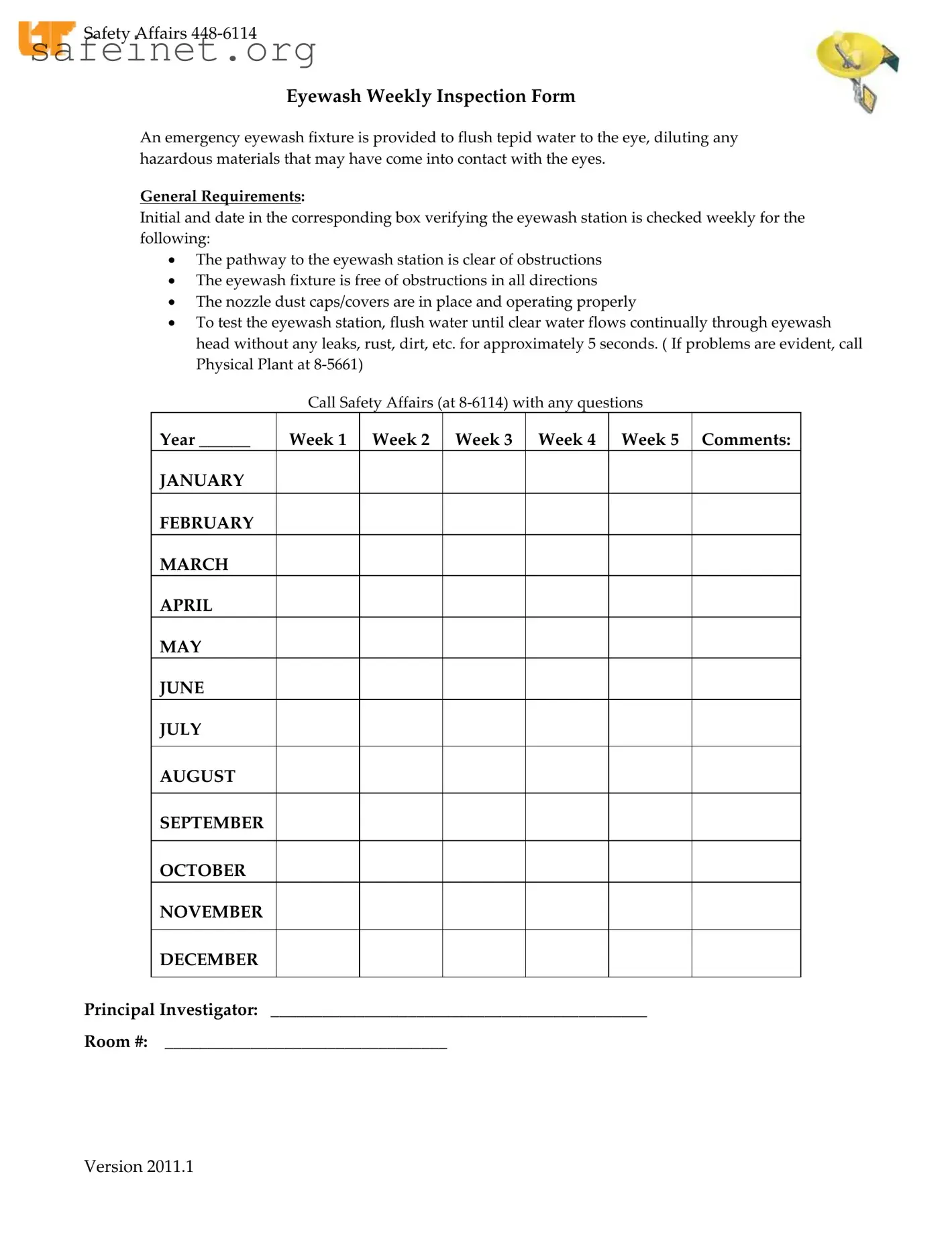

How do I document the inspection findings?

You can document your inspection findings directly on the Eyewash Station Log Sheet. Each week, initial and date in the designated box after you complete the inspections. There is space to record comments, which can be useful for noting any observations or concerns you might have regarding the eyewash station's condition. Keeping accurate and timely records is essential to ensure compliance and safety standards.

Safety Affairs

Safety Affairs